Fabric Knowledge

Choosing a fabric is not as easy as it may look. There are pivotal characteristics that need to be understood before an informed choice can be made.

Here we have outlined some of the major factors to take into consideration when choosing a fabric.

Types of Upholstery Fabric

Cotton: Cotton is a natural fibre and is regarded highly for its breathability and comfort. Cotton is diverse in the colours and patterns it may be available in as well as being easy to clean. Some of our prints like Fernbrook & Nova are made of a cotton blend.

Linen: Linen is a natural fibre that is highly breathable and known for its relaxed and casual look. Linen is made from the flax plant making it extremely strong and lightweight. While we don’t have any fabrics that are made from 100% linen our Trinity collection is made from a linen blend and is one of our most breathable fabrics.

Wool: Wool is durable and luxurious. Made from animal hair the fabric is sometimes scratchy and hard to clean meaning most of the time it is made with a blend of other materials.

Polyester: Polyester is a man-made, synthetic fabric. It offers strength, durability and resistance to fading and abrasion. The majority of our fabrics are made from 100% polyester meaning they are a great choice for commercial projects.

Velvet: Velvet upholstery showcases luxury and sophistication. Its soft touch is elegant and desirable. Velvet can be either synthetic or natural as it can be made from cotton, silk & polyester. Check out our 100% polyester, velvet-like fabric Keesha.

Leather: Known for not only its luxury but also its durability leather is easy to clean and an excellent choice for classic contemporary furniture.

Vinyl: Referred to mostly as ‘faux leather’ or PVC or PU it is an imitation of genuine leather. Vinyl is extremely durable and suited to high-traffic pieces like hospitality furniture or RV’s. Check our our vinyl, Viva.

Viscose: Viscose is a semi-synthetic fabric that is made from wood pulp. Viscose has a smooth, luxurious feel similar to silk.

Factors to Consider:

Aesthetics: The aesthetic of fabric ranges from the texture to the colour, either way, it could transform a room or make it boring. Think about colour palettes and coordinates. Don’t be afraid to mix in some patterns along with plain fabrics. It’s all about the kind of tone and mood you want someone to feel when they see the piece. For some inspiration check out our colour blogs.

Comfort: Most of the time furniture is going to be felt or sat on. Soft and plush fabrics help entice people to want to relax whereas fabrics like silk and jacquards create a more formal type seating.

Durability: Fabrics are tested by the Martindale and Wyzenbeek test. This is a form of rub test to understand how much use it can withstand. In Australia, any fabric that tests over 30,000 Martindale rubs is considered heavy commercial and is made to sustain high traffic. Generally, most residential fabrics will fail into the general or heavy domestic rating.

Maintenance and Allergies: Some fabrics are easy to clean with general soap and water. Others like silk, velvet & linen may require professional cleaning. To get the best use out of our fabrics check out our page Care & Advice.

Understanding Plain Fabrics

Plain fabrics have no complex designs. They are generally made up of simple weaves such as hopsacks, twills, herringbones and satins. Most plain fabrics are made from polyester, cotton, linen, leather, wool etc. Sometimes they are made from a mix of these specifically a majority of polyester mixed with a natural fibre. Plain fabrics are perfect for a minimalistic and modern style that relies on colour and texture for a room.

Understanding Pattern Fabrics

Pattern fabrics are mostly made by two methods, either printed or woven. Printed fabrics is an ancient textile method but coming into the 21st century the industry has seen revolutionary upgrades.

Burn out printing: Uses chemicals to ‘burn’ one fibre in a fabric. This creates a sheer design on a solid fabric making the handfeel soft and luxurious

Digital printing: This is a new printing method that is popular for its precision and affordability. And design can be printed onto fabric and there are no colour restrictions.

Engraved roller printing: This technique is used for the majority of print fabrics worldwide. The colours are transferred by one roller per colour.

Hand block printing: This is the oldest for of printing where dyestuffs are applied by wooden, linoleum or copper blocks.

Transfer paper printing: This technique uses heat and pressure to transfer a design onto fabric though generally it’s used in polyester and cotton blends.

The other technique of achieving pattern is by weaving it into the fabric. These are commonly referred to as ‘Jacquards’. The jacquard loom was created in 1804 by a weaver Josep-Marie Jacquard in France. To identify a jacquard you can look at the backing and identify long floats. The process of making the jacquard is what makes the fabric so special as the patterns aren’t decorative accents but rather an integral part of the entire fabric.

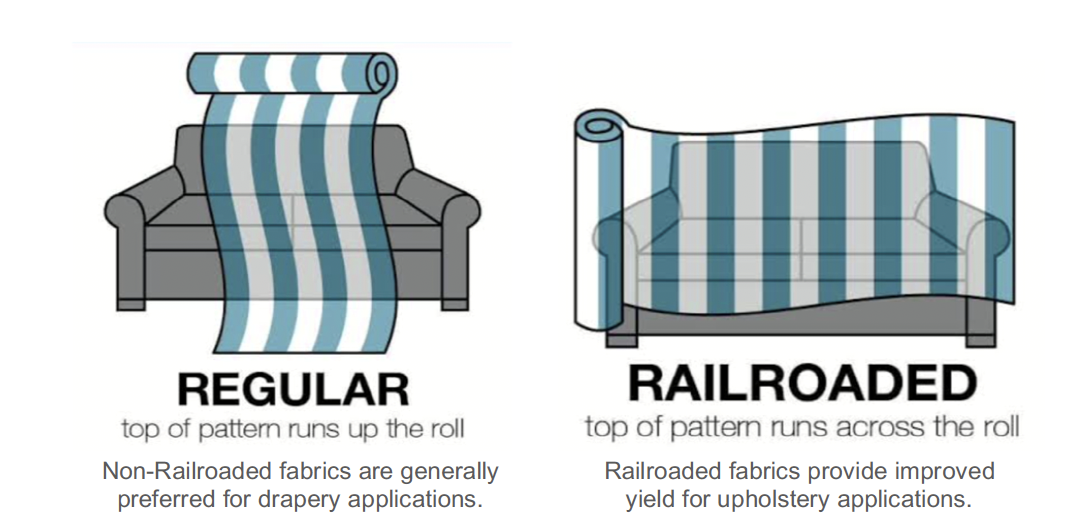

Railroaded vs. Non Railroaded

When selecting a fabric it’s important to know if it’s railroaded or not. Fabrics that are not railroaded run up the roll and are better for decorative pieces like cushions and throws. However when the pattern runs with the roll, from left to right, it is railroaded. This means it’s better for larger pieces of furniture as the pattern will repeat neatly and continuously.

Fabric Testing

Before selecting a fabric it’s important to know its capabilities. Therefore all fabrics, before they reach the market, are tested in various methods. Here are some of the most common.

Abrasion Tests: In order to meet specific standards a fabric will undergo a Martindale or Wyzenbeek test that involves a machine rubbing against the fabric, it doesn’t switch off until the fabric begins to wear down. After this process the number of rubs (machine going back and forth) is calculated and the fabric is given a rating. In Australian standards anything over 30,000 Martindale rubs is considered heavy commercial but at Profile Fabrics we’ve increased this to 40,000 for extra guarantee.

Seam Slippage: Seam slippage is the separation or pulling apart of yarns in a fabric usually along a sewn seam or join. A fabric must not exceed 6mm to pass. Seam slippage usually occurs on joins that are subject to heavy load and pressure.

Piling Resistance: Piling refers to the small fluffy balls of fibre on a fabrics surface. This generally is caused by wear and abrasion as loose fibres become tangled. This test will determine how resistant fabrics are to piling or fuzzing. Usually the fabric is rubbed against another fabric to determine this. A fabric must receive a rating of minimum 3-4 to pass.

Colourfastness to Light: Colourfastness to light measurers a fabrics resistance to colour loss due to UV light. In a controlled condition the fabric is put under an artificial lamp to replicate the effects of natural light exposure. It is then compared to a piece of the original fabric (generally after 40 hours) and is given a rating on the “blue scale'“. For general/heavy domestic a minimum of 4-5 is needed for medium to darker colour fabrics and for heavy commercial a minimum of 6 is required for medium to darker colour fabrics.

Colourfastness to Rubbing: This method is commonly referred to as ‘crocking’ and tests a fabrics resistance to colour loss when subjected to rubbing or friction. This is important for upholstery fabrics as people want to be confident about what they wear on a piece of furniture. A fabric must receive a result of 4 or above for both dry and wet rubbing.

Free and Hydrolysed Formaldehyde: This test specifies a method for determining the amount of free formaldehyde and formaldehyde extracted partly through hydrolysis by means of a water extraction method. The lower limit is 16mg/kg. Below this is reported as “not detectable”.

Fire Retardancy: All fabrics are flammable to some degree. Measuring fire retardancy determines how the big a flame became on fabric, the amount of charring afterwards and any remaining flame residue.

Fabric Weaves

The warp is the long yarn that runs vertically up and down the roll of the fabric. The weft is the yarn that passes horizontally across the fabric roll. There are many different types of woven fabrics such as:

Plain weave: Warp and weft align so they a form a simple criss-cross pattern.

Dobby weave: This fabric is produced on the lobby loom and is characterised by small geometric patterns and extra texture.

Jacquard weave: These fabrics are produced on a jacquard loom. The designs are endless and complex both plain and pattern fabrics can be woven on jacquard looms.

Corduroy: This fabric has a distinct raised cord or wale texture. It looks as though it is made from multiple cords laid parallel to each other.

Twill weave: This effect is made by weaving one or more warp fibres over and under one of more weft fibres. This is common in denim fabrics.

Herringbone: A variation of the twill weave. It is called herringbone as it resembles that of the skeleton of herringbone fish.

Pile fabric: Extra sets of warps or fillings are woven over ground yarns of plain or twill weave to form loops. Pile fabrics have been defined as fabrics with cut or uncut loops which stand up densely on the surface.